PURGESTATION: The ultimate machine for inkjet printhead maintenance

PURGESTATION is the most advanced solution for inkjet printhead maintenance.

With 3 independent stainless-steel circuits, each capable of handling up to 2 printheads simultaneously and working with different liquids (ink or cleaner), it delivers unmatched versatility in the market.

- Massive purge of printheads with cleaner.

- Priming with ink for immediate printing startup.

- Up to 6 printheads in parallel, even from different brands.

- Automatic recovery of cleaner or ink, reducing costs.

With PURGESTATION, your company ensures productivity, resource savings, and maximum reliability in every process.

PURGESTATION: Industrial machine for purging and priming inkjet printheads

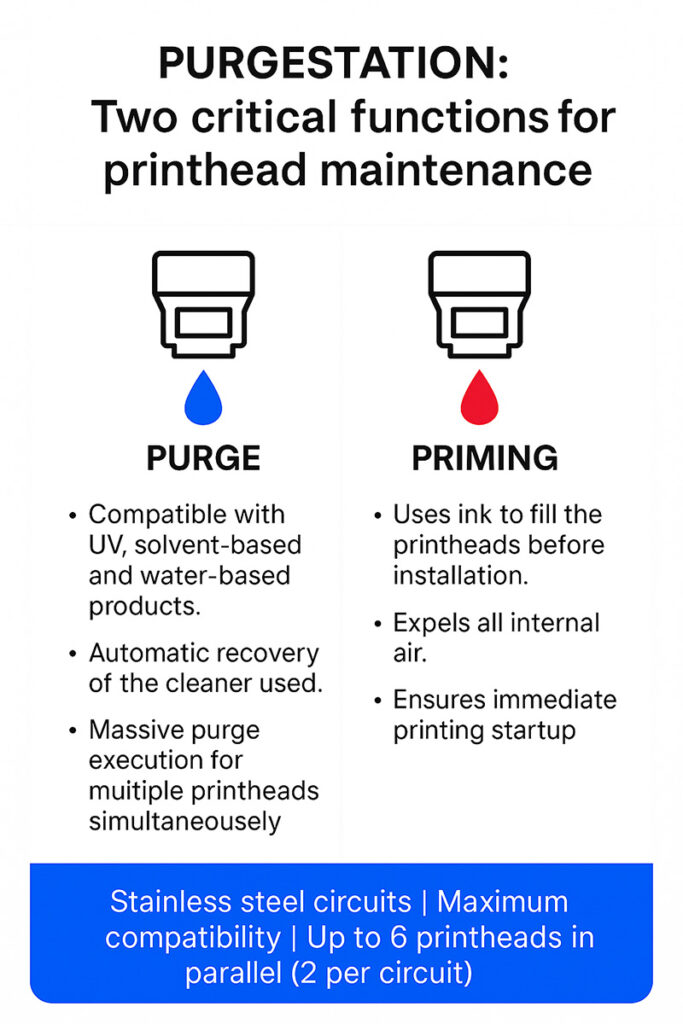

PURGESTATION is the most complete and reliable solution on the market for the maintenance of industrial inkjet printheads. Its design is focused on ensuring maximum performance in two critical functions: massive purge of printheads and priming prior to installation.

- Purge function of inkjet printheads

PURGESTATION enables massive purging of inkjet printheads with total precision using cleaner. The system offers the option to reject or recover the cleaner used during the process, optimizing resources and reducing waste.

Thanks to its 3 independent circuits for maximum versatility, each one can handle up to 2 printheads simultaneously, reaching a total of 6 printheads in parallel, even of different brands and models.

Each circuit has configurable recipes that allow absolute control over critical parameters such as pressure, temperature, flow rates, purge times, and operating modes.

In addition, the stainless-steel circuits ensure full compatibility with aqueous solutions and maximum durability in demanding industrial environments.

- Priming function of inkjet printheads

In addition to purging, PURGESTATION provides the priming function. This process consists of recirculating ink through the printheads, completely eliminating internal air.

The result is immediate: once installed in the printer, the printheads are ready to print without waiting times, leading to greater operational efficiency and fewer production downtimes.

The modular design of PURGESTATION allows simultaneous priming of up to 6 printheads, with the same flexibility of recipes and configurable parameters as in the purge mode.

Key technical features of PURGESTATION

- 3 independent circuits for maximum versatility, each capable of handling 2 printheads simultaneously.

- Compatibility with different liquids: each circuit can contain a different liquid —cleaner or ink— depending on process needs.

- Stainless-steel circuits, ensuring resistance and compatibility with aqueous solutions.

- 15 litres main tanks per circuit for high performance.

- 5 litres waste tanks per circuit, with an intelligent maximum-level alarm system. When the tank reaches capacity, the machine automatically stops to prevent overflows and ensure safe operation.

- Universal head support adaptable to any brand and model of inkjet printhead.

- Multicolor internal beacon with real-time status indicators for each circuit.

- Advanced graphical interface, fully intuitive and customizable.

- Predefined and configurable recipes, optimized for different types of printheads and fluids.

- Independent parameter adjustment per circuit for temperature, pressure, flow rates, and timings.

- Minimal maintenance, designed for high-demand industrial environments.

Key benefits for the industry

- Resource optimization: recovery of cleaner or ink, depending on the liquid used in each circuit.

- Maximum compatibility: suitable for any inkjet printhead on the market.

- Higher productivity: capability to purge or prime up to 6 printheads simultaneously, even of different brands and models.

- Operational flexibility: each circuit can work with a different liquid (cleaner or ink).

- Durability and reliability: stainless-steel circuits, resistant to aqueous solutions and intensive processes.

- Immediate performance (only in priming): printheads ready to start printing instantly once installed in the printer.