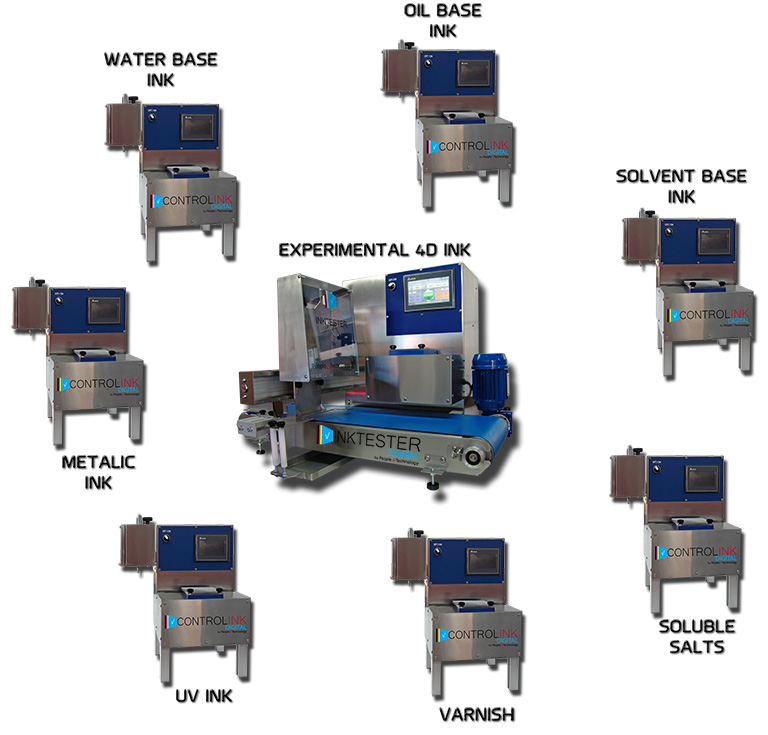

Controlink: scalable flexibility for inkjet ink control

Controlink is a modular system designed to progressively expand laboratory capacity for inkjet ink control and development, in combination with Inktester Digital. Its scalable design allows laboratories to adapt the number of active tests and projects to real growth needs, without structural limitations.

By integrating multiple Controlink modules, laboratories increase operational independence and gain the ability to perform simultaneous tests with different inks, including incompatible formulations, enabling parallel work by multidisciplinary teams without project interference.

Each Controlink features an independent ink circuit, allowing objective ink comparison under identical test conditions, parallel work with reference and optimized formulations, and long-term stability testing.

In addition, Controlink supports simultaneous evaluation of color sets and direct printing on plotters, expanding laboratory versatility in R&D and quality control environments.

👉Contact us to learn more about Controlink’s capabilities.

Controlink: total scalability for inkjet ink development

Controlink, in combination with Inktester Digital, allows laboratories to progressively expand their capacity for inkjet ink control and development. Its modular design removes any limitation on the number of tests or projects, adapting to the real growth of the laboratory.

As many Controlink modules as required can be added whenever needed. The more Controlink units are integrated, the greater the operational independence and the ability to perform simultaneous tests with different inks, optimizing the use of Inktester Digital across multidisciplinary teams.

Advantages of integrating Controlink

- Unlimited laboratory scalability.

- Increased capacity for simultaneous ink testing.

- Parallel work by multiple technicians without project interference.

- Independent management of inks and parameters per module.

Independent ink circuits

Each Controlink integrates a fully autonomous ink circuit, designed to operate independently from other tests.

This enables:

- Simultaneous testing of incompatible inks.

- Project-specific working conditions.

Ink comparison and optimization

Controlink enables direct ink comparison under identical test conditions, keeping parameters such as temperature, flow rate, pressure and waveform constant, while varying only the formulation.

It also allows parallel work with a reference ink and optimized versions, enabling controlled comparison of formulation evolution.

Long-term testing and versatility

- Ink recirculation over several days with temperature and meniscus control.

- Sedimentation testing without interrupting other tests.

- Simultaneous evaluation of color sets.

- Direct printing on plotters.